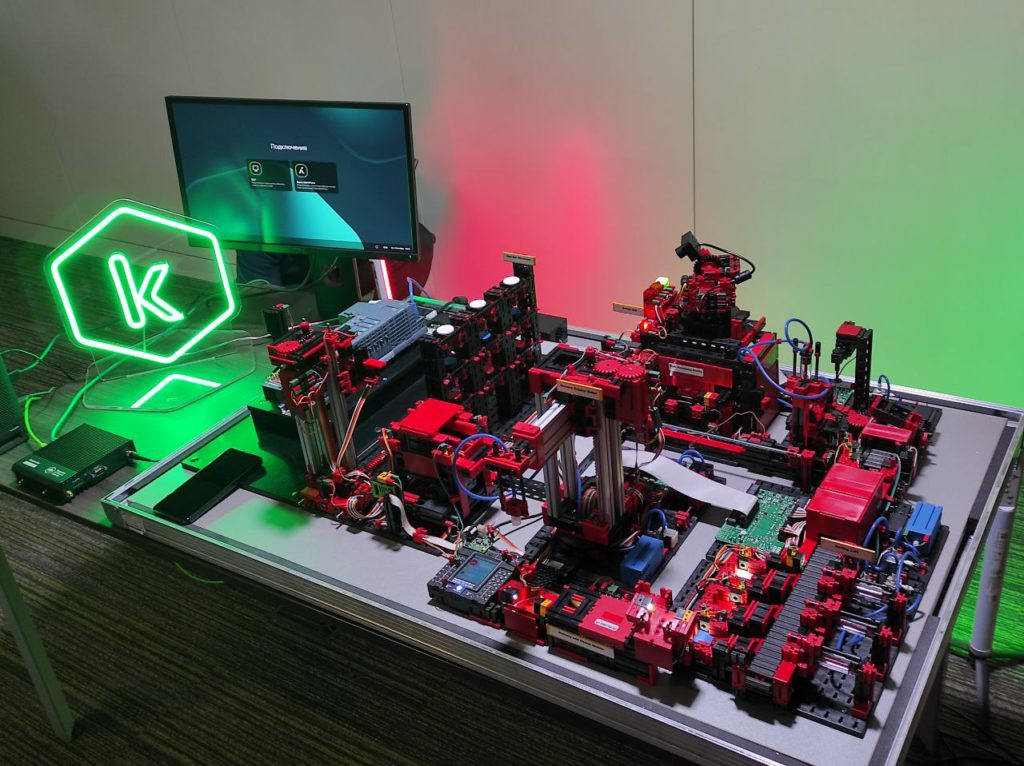

Kaspersky Smart Factory is a testbed for simulating real attacks on factory infrastructure and applying Cyber Immune solutions on a small scale before implementation.

The factory model allows to plan, program, develop and test industrial controls with the corresponding software in a realistic and cost-effective manner before large investments are made. It can be used in the areas of education, development, simulation and presentation.

Cloud-based dashboard enables factory model to be displayed from three different perspectives.

Customer view. Allows to order a workpiece and track the current status of he order in the shopping cart.

Supplier view. Depicts the process of ordering the raw materials.

Production view. Dashboard allows to view factory status, the production process, the stock, the NFC reader and the sensor values. Also user can monitors production line with a camera.

Cyber Immune and other Kaspersky products covering cybersecurity needs of industrial enterprises and critical infrastructure operators

Opportunity to try Cyber Immune approach to protecting the IT and OT circuits of an industrial enterprise.

Assistance in creating digital services for process control and data analysis

A training model factory Simulation from Fischertechnik. The test environment consists of several technological modules:

Modeling of plant-specific processes. Ability to test various attack scenarios.

Convenient and customizable dashboard. A wide range of devices for monitoring and managing technological processes of the factory model.

Application for mobile devices running on KasperskyOS for Mobile for working with a factory training model. Application provides capabilities for production processes management.

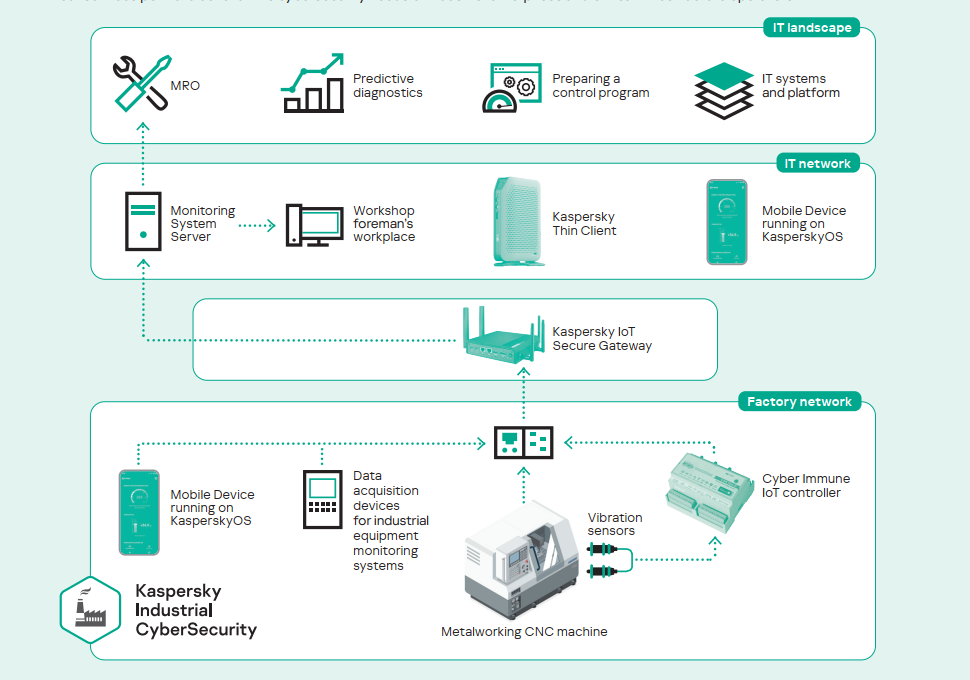

Kaspersky IoT Secure Gateways (KISG) provide connection between the factory stand and the cloud platform. At the same time, a Cyber Immune approach is used to organize a data transport channel from the production level to the platform level.

There are two possible scenarios for transferring data from the digital factory stand to the cloud platform.

1. Unidirectional data transmission via software data diode KISG 100

KISG 100 connects directly to the PLC, which controls all technological processes in the factory, collects data via OPC UA, converts and transmits it via the MQTT protocol to the cloud platform.

2. Bidirectional data transmission via the universal gateway KISG 1000

KISG 1000 is located at the network edge of the fabric and provides bidirectional data transfer between the fabric and the platform through the creation of an MQTT Bridge connection

between the broker on the gateway and the remote broker on the platform. The gateway is also a router with a Firewall and contains functionality for detecting and preventing attacks from outside (IDS/IPS).

Kaspersky Thin Client provides secure access to a remote desktop and serves as a substitute for a local workstation. On its basis, the workplace of an automated process control system operator is modeled.